Manual lifter KET-LIFT4BOX with Mounting Platform

€2,700.00

Available in 30 days, delivery time 1-3 days

Description

Product information "Manual lifter KET-LIFT4BOX with Mounting Platform"

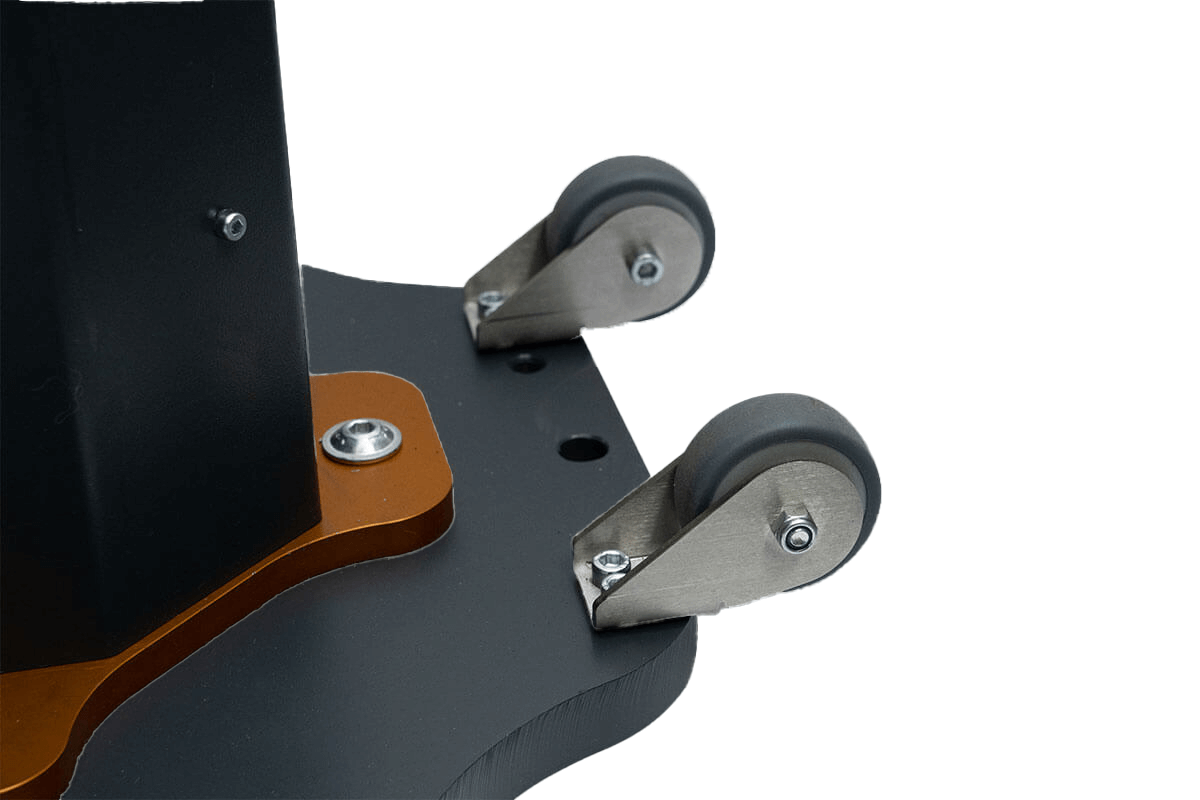

Mounting plate 1 m x 0.6 m | manually adjustable working height | maintenance-free | transport wheels for mobile use

The manual lifting device KET-LIFT4BOX is a compact, powerful, and easy-to-operate solution for efficiently lifting KLT containers, blisters, or other industrial containers in warehouses, workshops, and production facilities.

KET-LIFT4BOX is perfect for heavy loads in demanding environments. Thanks to its manual lifting function and ergonomic design, it relieves workers and shortens the reach. It is thus the ideal assistant for improved material provision and a healthier, more productive work environment.

Key Features

- Suitable for front loading up to 80 kg

- High stability thanks to solid base plate

- Transport wheels for mobile use

- Ergonomic working thanks to continuous manual container positioning via power drill on the column

- Maintenance-free

Technical Data

- Maximum load capacity approx. 80 kg

- Dimensions (W x D x H) 560 x 640 x 1,125 mm

- Working height 100 to 925 mm

- Total adjustment path 825 mm

- Own weight approx. 55 kg

- Operation via power drill on the column

- Transport wheels

Scope of Delivery

- Steel lifting column

- Mounting plate 1 m x 0.6 m

safety instructions

Read the safety instructions and information on safe operation before beginning any handling activities with the KetLift4Box.

Keep this operating manual carefully.

It is very important for your safety that you have understood and follow all sections related to safety.

Ignoring the safety instructions can lead to risks to life and health of individuals and significant property damage.

Personnel - Qualification and Responsibilities

Information:

All handling activities with the KetLift4Box may only be carried out by qualified and competent personnel.

The qualified and competent personnel must:

▪ Know the applicable accident prevention regulations and safety instructions in the operating manual.

▪ Know the safe behavior in case of defects in the KetLift4Box.

▪ Have the physical and mental abilities to handle the KetLift4Box safely.

Operator Responsibilities

Every person working with the KetLift4Box has a duty to contribute to its safety and health.

▪ Ensure that only qualified and competent personnel handle the KetLift4Box.

▪ Avoid unsafe and dangerous work with or on the KetLift4Box.

▪ Report any safety defects immediately to a supervisor during the handling of the KetLift4Box.

General Safety Instructions

Follow these general safety instructions during all handling activities with the KetLift4Box:

Risk of electric shock due to damaged live electrical equipment.

• Do not perform activities if the electrical equipment is damaged.

▪ Have maintenance and safety inspections performed only by specialists or the manufacturer.

Electrical hazard due to liquid ingress into the KetLift4Box.

• Prevent liquids from entering the interior of the KetLift4Box.

Risk of entanglement, trapping, or catching by the rotating spindle drive system.

• Do not reach into moving parts during operation.

Risk of tipping or falling parts.

• Ensure the stability of the KetLift4Box.

• For a 200 kg load, anchoring the base plate to the floor is recommended.

• Do not use the device as a hand truck / pallet jack.

Crushing and impact risk from the lifting movement.

• Ensure that no persons or objects are in the danger area of the KetLift4Box.

Risk of breakage due to incorrect assembly or failure to observe permissible operating data.

• Follow all safety instructions and information in this manual during assembly, commissioning, and operation.

Risk of falling loads due to incorrect loading.

• Follow all instructions for safely loading the KetLift4Box.

Risk of uncontrolled movements due to dirty automatic sensors.

• Keep the automatic sensors clean.

• Check the switching function of the sensors before each use.

Risk of cuts from dangerous surfaces.

• Wear suitable protective gloves.

Tripping and falling risks from the base plate and transport rollers.

• Be aware of tripping hazards from the step on the base plate and the transport rollers.

Emergency Stop / Emergency Halt

▪ There is an emergency stop button on the lifting column and an emergency halt button on the handheld control device. In dangerous situations, immediately press one of the two buttons.

▪ After pressing the emergency halt button, the movement of the KetLift4Box will stop immediately. Please note that the KetLift4Box will NOT be electrically deactivated.

▪ After pressing the emergency stop button on the lifting column, the movement stops and the KetLift4Box is electrically deactivated. However, note that residual voltages may remain in the system for up to 5 minutes.

▪ Before resetting the emergency halt / emergency stop, the cause of the hazardous situation must be eliminated.

▪ To reset the emergency halt button, turn the actuator on the handheld control device left or right until it springs back. The emergency stop on the lifting column is unlocked by pulling it back.

Automatic Sensors

▪ Do not look directly into the sensors!

▪ Keep the automatic sensors clean.

▪ Contaminations can cause incorrect signals and result in uncontrolled movements.

▪ Check the switching behavior before each use, see the "Maintenance" section.

▪ Follow the manufacturer’s operating instructions included with the device!

Safety Zone

▪ The safety zone extends from the floor up to a height of 120 mm above the base plate. In this zone, the device can only be operated in manual mode.

Avoiding Liquid Ingress

▪ Prevent liquids from entering the housing of the KetLift4Box. The guide and spindle drive system, as well as the handheld control device, can be damaged by liquid ingress, which poses a risk of short circuit.

Intended Use

The electrically operated box lifter KetLift4Box is designed to lift loads up to 200 kg to an ergonomic working height using its integrated motor-driven spindle system. The load, preferably in the form of boxes, crates, or similar containers, must be the correct size to fit the load carrying means. Other loads must be designed to sit securely on the forks and not slip. The loads can be moved manually or automatically in sensor mode. It is prohibited to lift or lower living beings (people or animals). The KetLift4Box is intended for industrial use in indoor environments.

Foreseeable Misuse

In case of misuse, Ketterer is not liable for material or personal damages as well as any consequential damages.

Misuse may include:

▪ Ignoring permissible operating data and usage instructions.

▪ Use in outdoor areas.

▪ Ignoring assembly instructions.

▪ Lifting and lowering living beings (people or animals).

▪ Operating within the danger zone.

▪ Using as a hand truck / pallet jack.

Residual Risks

Despite all measures taken to integrate safety in design, safety features, and additional safety instructions, residual risks cannot be completely eliminated. You can reduce residual risks by following the safety instructions and using the KetLift4Box only for its intended purpose. Residual risks may include:

▪ Risk of cuts from dangerous surfaces.

▪ Tripping and falling risks from the base plate and transport rollers.

▪ Crushing or impact risks from the lifting movement.

▪ Risk of uncontrolled movements of the spindle drive system due to overloading.

▪ Risk from insufficient or missing maintenance, as well as mechanical and electrical inspections.

▪ Risk from unsecured loads or improper loading.

Reviews 0

Login