Motor drive for through going spindle 4779

| Quantity | Unit price |

|---|---|

| To 4 |

€132.70

|

| To 9 |

€123.85

|

| To 19 |

€115.00

|

| From 20 |

€106.15

|

Available, delivery time: 1-3 days

Description

Product information "Motor drive for through going spindle 4779"

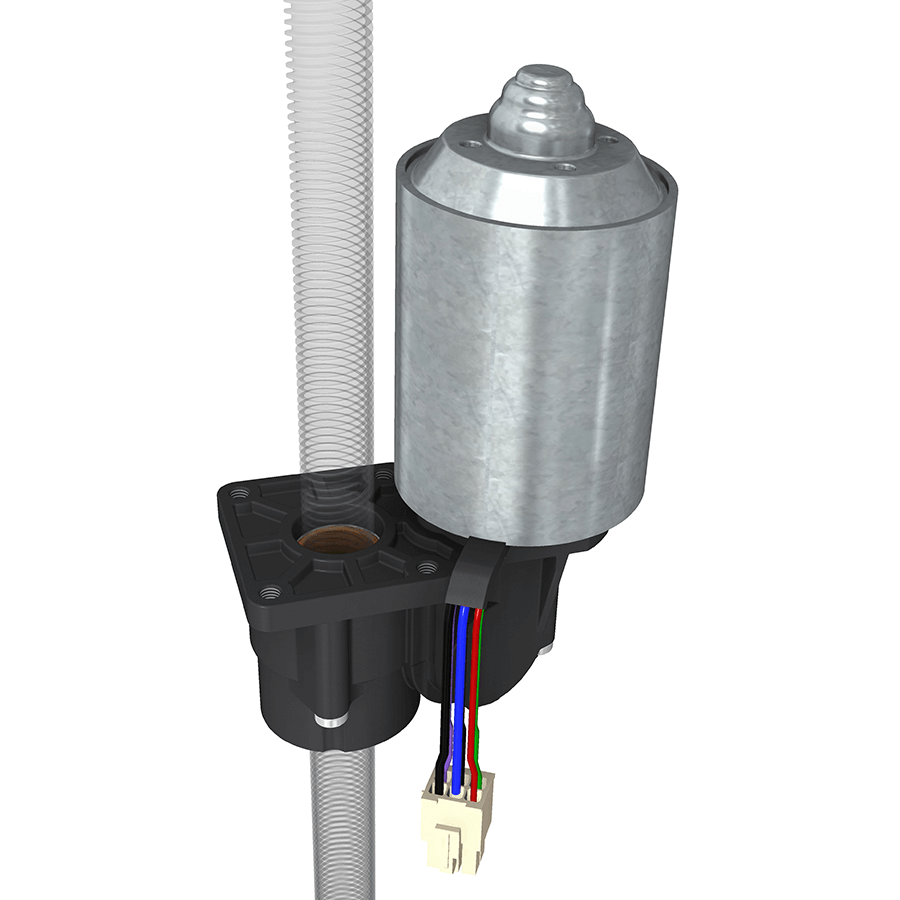

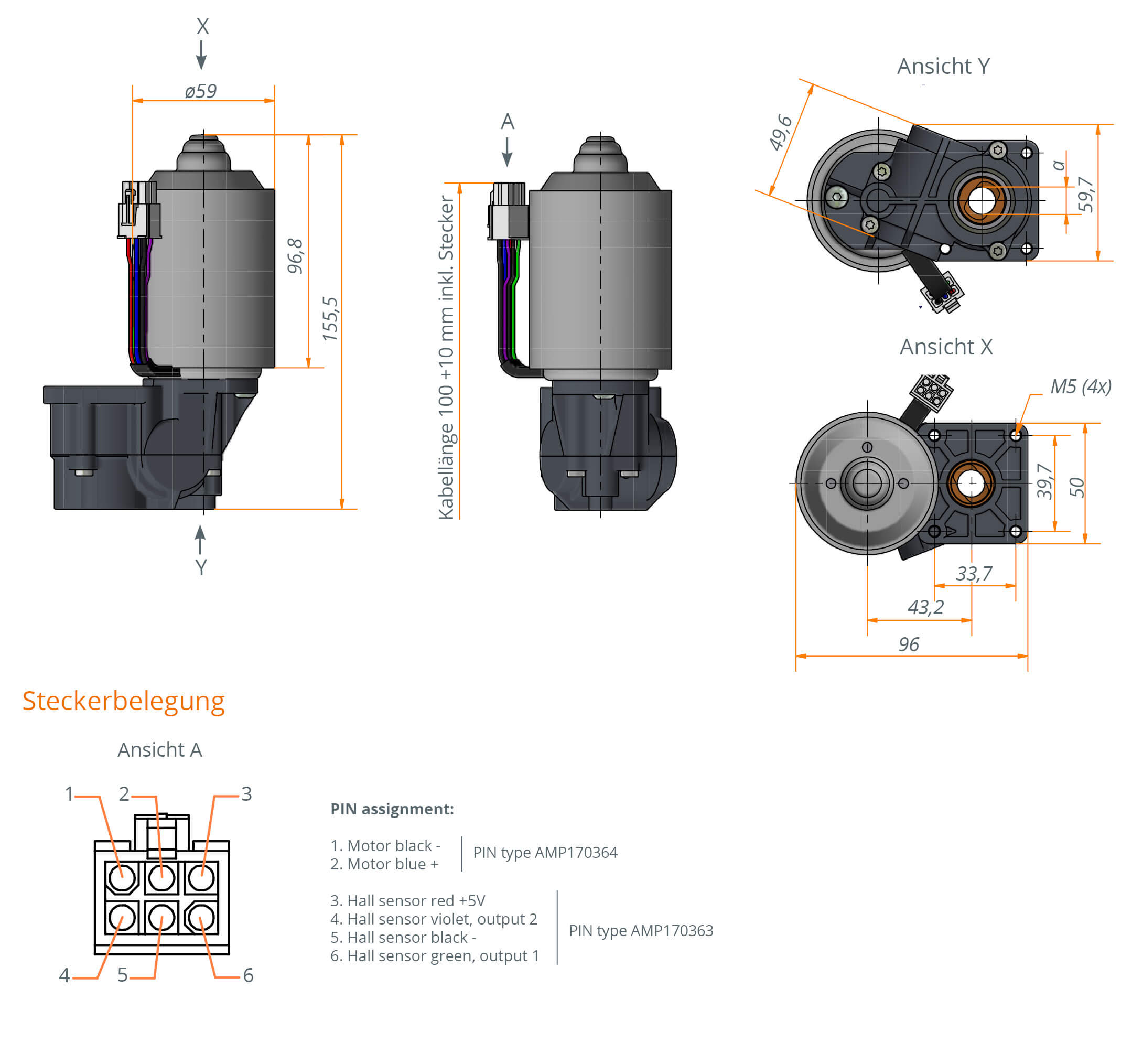

Powerful 24V DC motor with worm gear, specifically designed for a coaxial continuous spindle. Ideal for use in lifting columns. The drive is suitable exclusively for axial compressive loads. Thanks to a cable with a standard connector and integrated Hall sensors, the system can be operated easily and safely.

Special Features

- Two integrated Hall sensors for detecting rotations and direction of rotation

- Selection of internal thread types for the continuous spindle

- Excellent self-locking properties

- High speed and performance

- Spindle available separately

Variant Key

The variants differ in the types of internal threads used for securing the spindle.

Technical Data

| Model | 4779.00-0001 | 4779.00-0002 | 4779.00-0003 |

| Motor |

DC motor 24 V |

DC motor 24 V |

DC motor 24 V |

|

Sensor/Power supply |

Hall/5 V DC/0.3 A |

Hall/5 V DC/0.3 A |

Hall/5 V DC/0.3 A |

|

Protection class |

IP30 | IP30 | IP30 |

|

Operating temperature |

0° to +30° |

0° to +30° |

0° to +30° |

|

Electric current (IN) at max. load |

6.3 A | 7 A | 7 A |

|

Idle running speed |

133 rpm |

133 rpm |

133 rpm |

|

Duty cycle idle speed |

20% (at 5 Min.) |

20% (at 5 Min.) |

20% (at 5 Min.) |

| Duty cycle nominal load* | 20 s ON 240 s OFF | 33 s ON 240 s OFF | 16 s ON 240 s OFF |

| Max. lifting force | 1800 N | 2200 N | 1500 N |

| Traverse speed (constant from F= 0 to Fmax.) | 17 mm/s | 12 mm/s | 24 mm/s |

| Static Self locking ** | 180 kg | 220 kg | 150 kg |

|

Output (Inner thread) | SG12x12P4 RH | Tr16x8P4 RH | SG14x16P4 RH |

* Load determined for service life of 10,000 double strokes

** In combination with controller, which has a short circuit brake

Technical Notes

- The spindle is not included in the delivery and must be ordered separately.

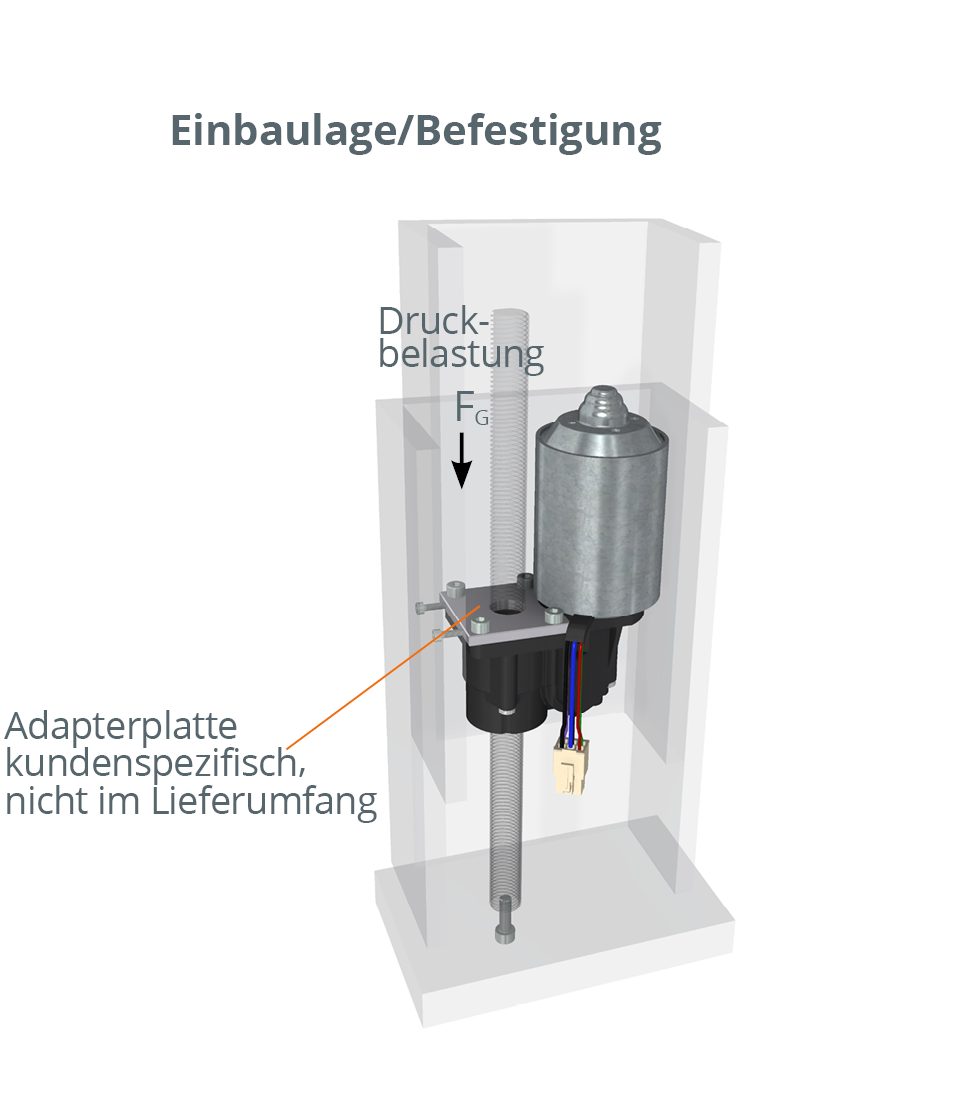

- Note: The drive is designed exclusively for axial compressive loads. Correct installation orientation must be observed (see installation example).

- Radial loads must be prevented by a separate guide system.

- The service life of the drive (10,000 double strokes) was determined within the operating range of the nominal torque.

- Using a controller with a short-circuit brake can significantly increase the holding torque of the drive.

- A controller* ensures that the travel speed remains as constant as possible across the entire operating range.

* Compatible with LogicData Compact-3 controller.

Documents 1

3D files

Note: The link will take you to our Nextcloud platform, where you

can directly download the STEP file. Please be aware that you will be

redirected to an external site.

Reviews 0

Login